STEP 1

Loading and unloading of raw materials

Our production chain starts with the delivery of raw materials that takes place in the tunnel. In this phase the components are sorted in dedicated workshops.

STEP 2

Cut

We have 2 cutting machines (saws) that handle one of rods and stems and the other of cutting other components. Once passed to the cut is the time of the lathes. We have 2 lathes, the largest in our possession, that work reeds long up to 10mt. Titan and Puma 700.

STEP 3

Production

We also have smaller size lathes and large size cutters that work all the components that will then be stored inside the 6 vertical warehouses Modula that we acquired in 2022

STEP 4

Modula Vertical Warehouse

After all the materials have been stocked, the welding or assembly phase can be carried out.

STEP 5

Welding

Welding is carried out manually or by automated robots. After a preliminary phase of washing the material, we weld the cylinders and/or other materials, which will then be supplied to the assembly department.

STEP 6

Assembly

After receiving the materials processed and welded, all components are assembled to obtain the finished product.

STEP 7

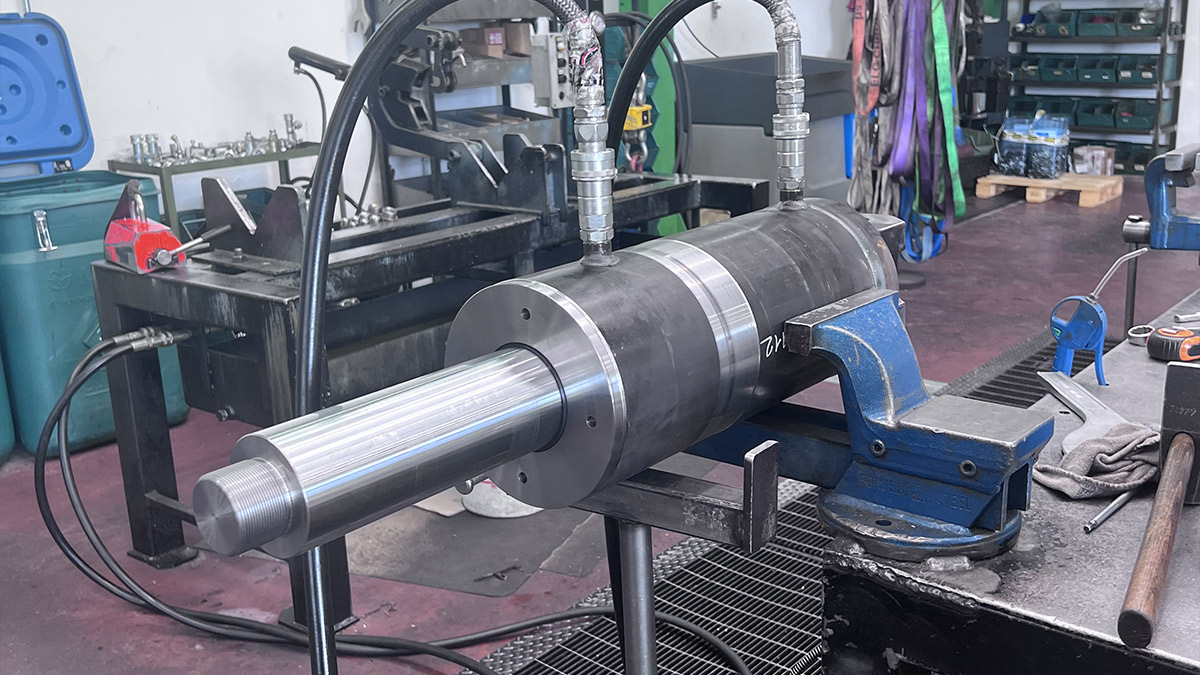

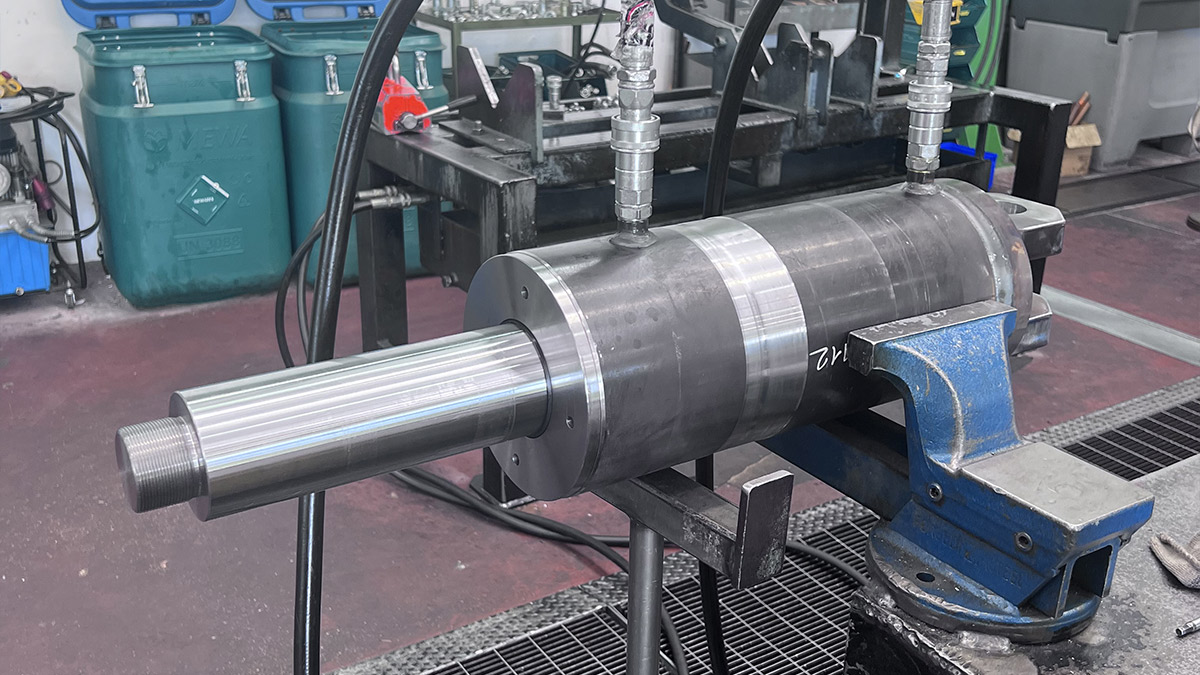

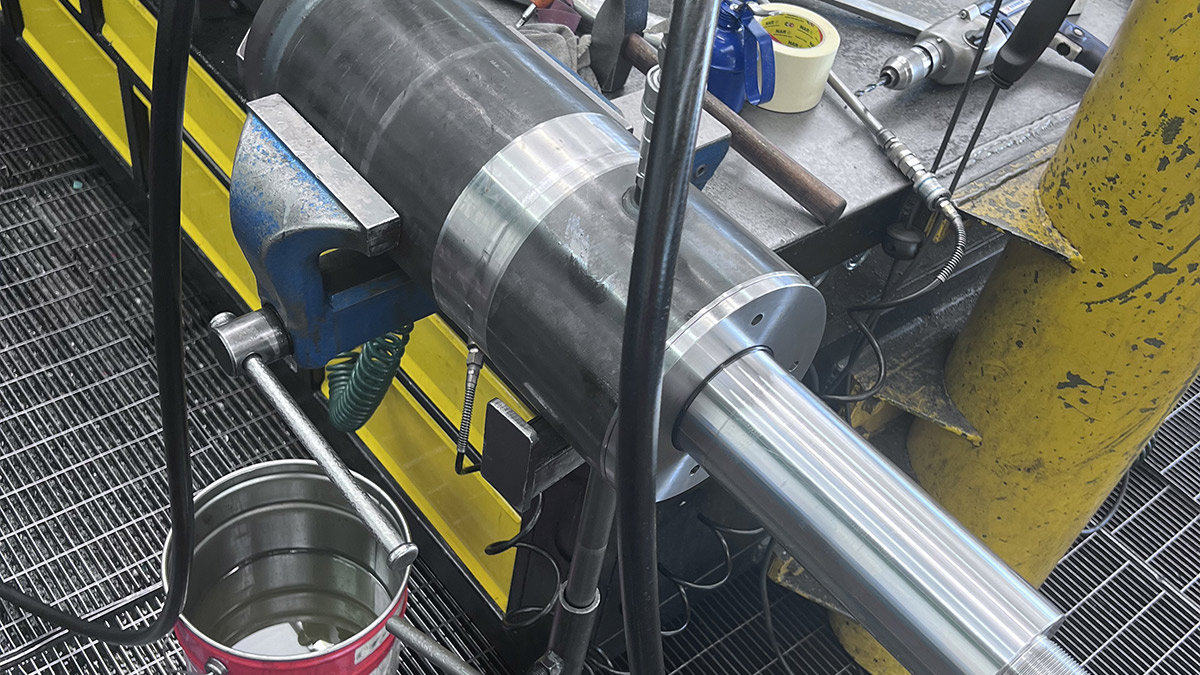

Testing

After assembly, the product passes to the accurate testing phase.

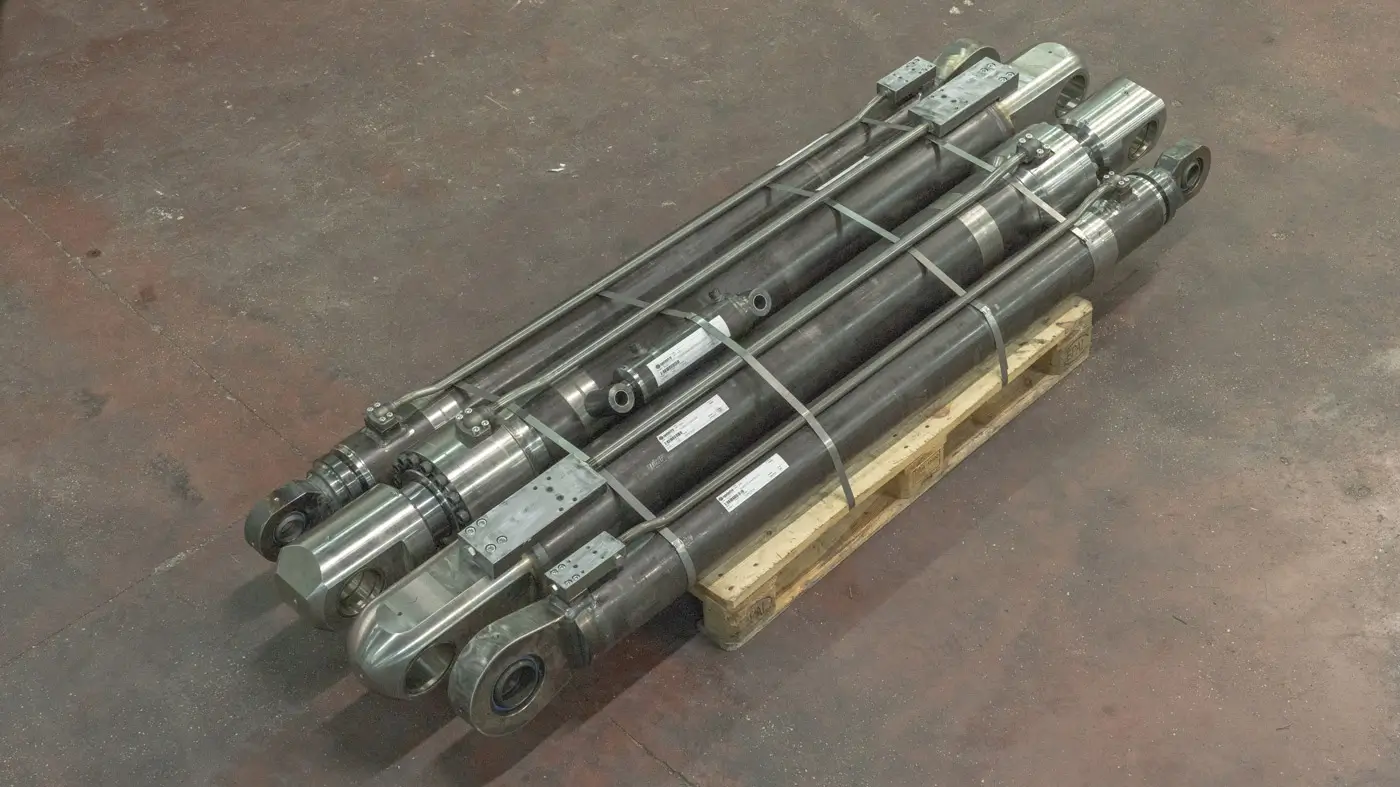

STEP 8

Shipping

After ensuring the correct condition of the product and after a detailed test, the product is ready for shipment to the customer.