When customization makes the difference

In the world of industrial plants, where precision and reliability are essential, special hydraulic cylinders stand out from standard cylinders because they can be customized to the specific needs of each customer.

These cylinders are made to measure, ensuring superior performance and an ideal solution for complex industrial and mechanical applications.

The construction types of hydraulic cylinders made to customer request are:

- Single-acting hydraulic cylinders (or single-acting)

- Double-acting hydraulic cylinders

- Plunging cylinders

- Telescopic cylinders

Cilindro a semplice effetto

I cilindri a semplice effetto permettono comunemente il controllo della sola estensione dello stelo, in quanto l’olio in pressione entra in una sola camera e può quindi comandare movimenti solo in una direzione.

Cilindro a doppio effetto

I cilindri a doppio effetto hanno la caratteristica di avere il fluido in pressione che può alimentare entrambe le camere, consentendo il controllo dei movimenti del pistone in entrambi i sensi.

Il controllo di quest’ultima in entrambe le camere del cilindro permette di governare con la massima precisione sia l'estensione dello stelo sia il suo ritiro.

Cilindro tuffante

I cilindri tuffanti possono compiere solo un’azione di spinta e a seconda delle necessità, possono essere dotati o meno di pistone di guida interno.

Questa tipologia viene utilizzata quando l’esistenza di una forza di contrasto di direzione garantisce il movimento di rientro nella posizione iniziale:

l’uscita è resa possibile dall’azione della pressione dell’olio sulle superfici del pistone, mentre il rientro è garantito dall’azione di una forza esterna.

Cilindro telescopico

I cilindrici telescopici permettono di raggiungere lunghezze elevate di sfilata a fronte di dimensioni compatte.

Grazie al rientro telescopico dei pistoni, l’ingombro è uguale alla corsa suddivisa per il numero di elementi più una quota fissa (spessore del fondello, lunghezza della guida, elementi di fissaggio).

Per una data corsa totale i cilindri telescopici possono essere costituiti a 2, 3, 4 o 5 elementi a seconda dei limiti di ingombro prefissati.

Let's now explore in detail the production and marketing process of special hydraulic cylinders

START

PRELIMINARY PHASE

The first phase of the process is crucial: the customer expresses the specific characteristics he wants for the cylinder.

This initial dialogue is the starting point, where ideas take shape.

Subsequently, our technical office carries out a feasibility study to carefully evaluate how to translate the customer’s needs into a practical and feasible solution.

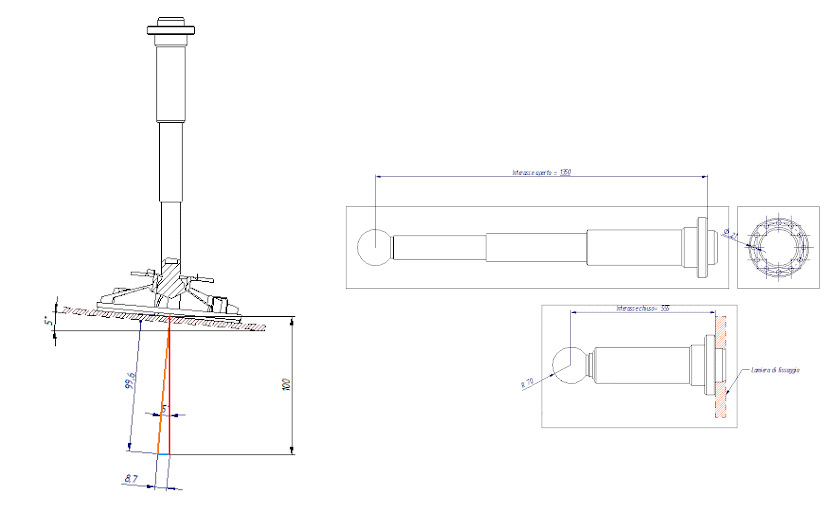

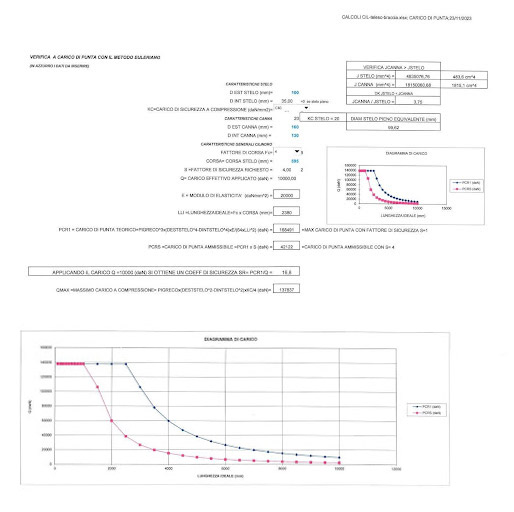

The stem is sized to satisfy the buckling test with the Eulerian method.

Quality and Durability

SELECTION OF MATERIALS

The choice of materials is essential to guarantee the performance of the cylinder over time.

The use of high-quality materials is preferred, preferably made in Italy, in order to guarantee maximum durability and robustness of the various components to create the finished hydraulic cylinder.

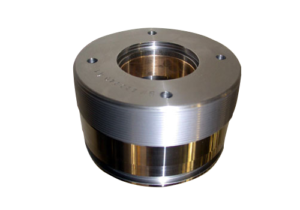

A hydraulic piston is basically composed of the following components:

CANNA

STELO

GUIDA

TESTA

FONDELLO

Furthermore, based on design or customer needs, they can be enriched with other components.

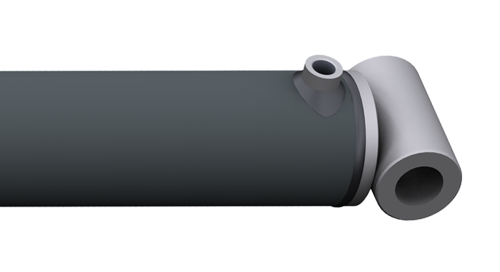

From ideas to realization

DESIGN

The design phase is a moment of great importance.

A team of highly qualified professionals, supported by advanced CAD design systems, translates the specific requests of the customer into a detailed project.

This step is crucial to ensure that the special cylinder is able to carry out the required work with maximum efficiency.

Often the project created does not exactly follow the customer’s request, therefore it is followed by other feedback proposals to improve the design already created.

The project is developed on the 3D Creo Element Direct Modeling program, whose technical specifications and advanced features allow the three-dimensional creation and subsequent layout of the assembly and all its components.

from art to innovation

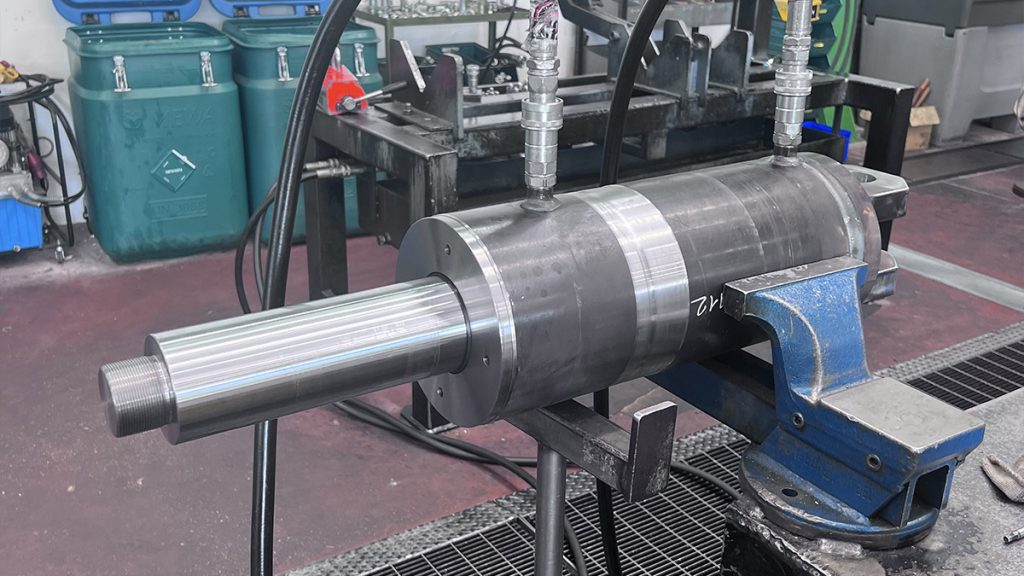

PRODUCTION

The production of a special cylinder is a largely artisanal process that combines human skill with the help of advanced technology machinery. It begins with the verification of the selected materials, followed by cutting the elements according to the project specifications. The use of highly technological and latest-generation machine tools guarantees precise processing. The welding phase is essential to guarantee the solidity of the cylinder structure, while the complete assembly is carried out with the utmost care and attention to detail.

quality assurance

TESTING

Testing is a critical phase of the process. Here, innovative technological tools are used to verify the conformity, robustness and stability of the cylinder. This phase ensures that the final product meets all customer requirements and is ready for use in the field.

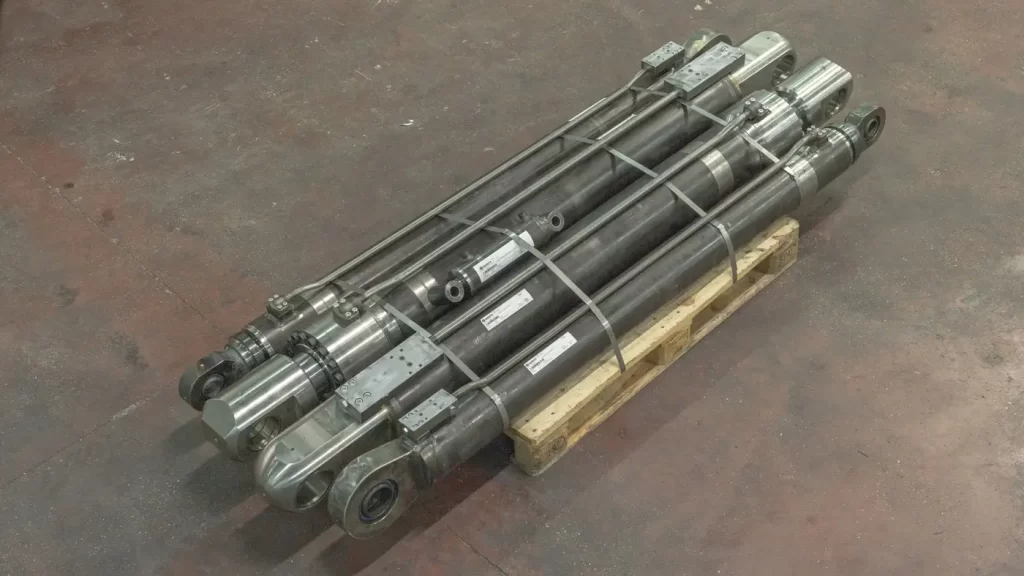

THE LAST PHASE

DELIVERY

After passing the rigorous testing control, the special cylinder is ready to be delivered to the customer. The packaging is made with extreme care to ensure that the cylinder reaches its recipient in optimal conditions.